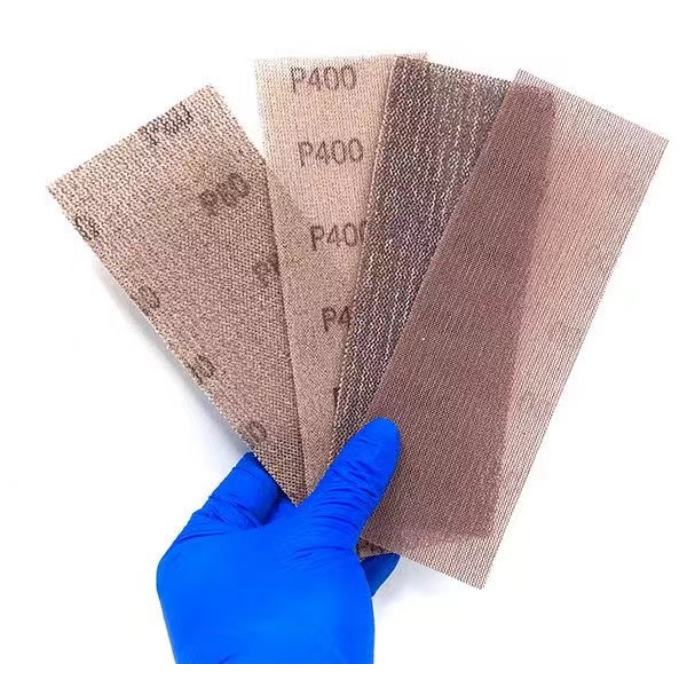

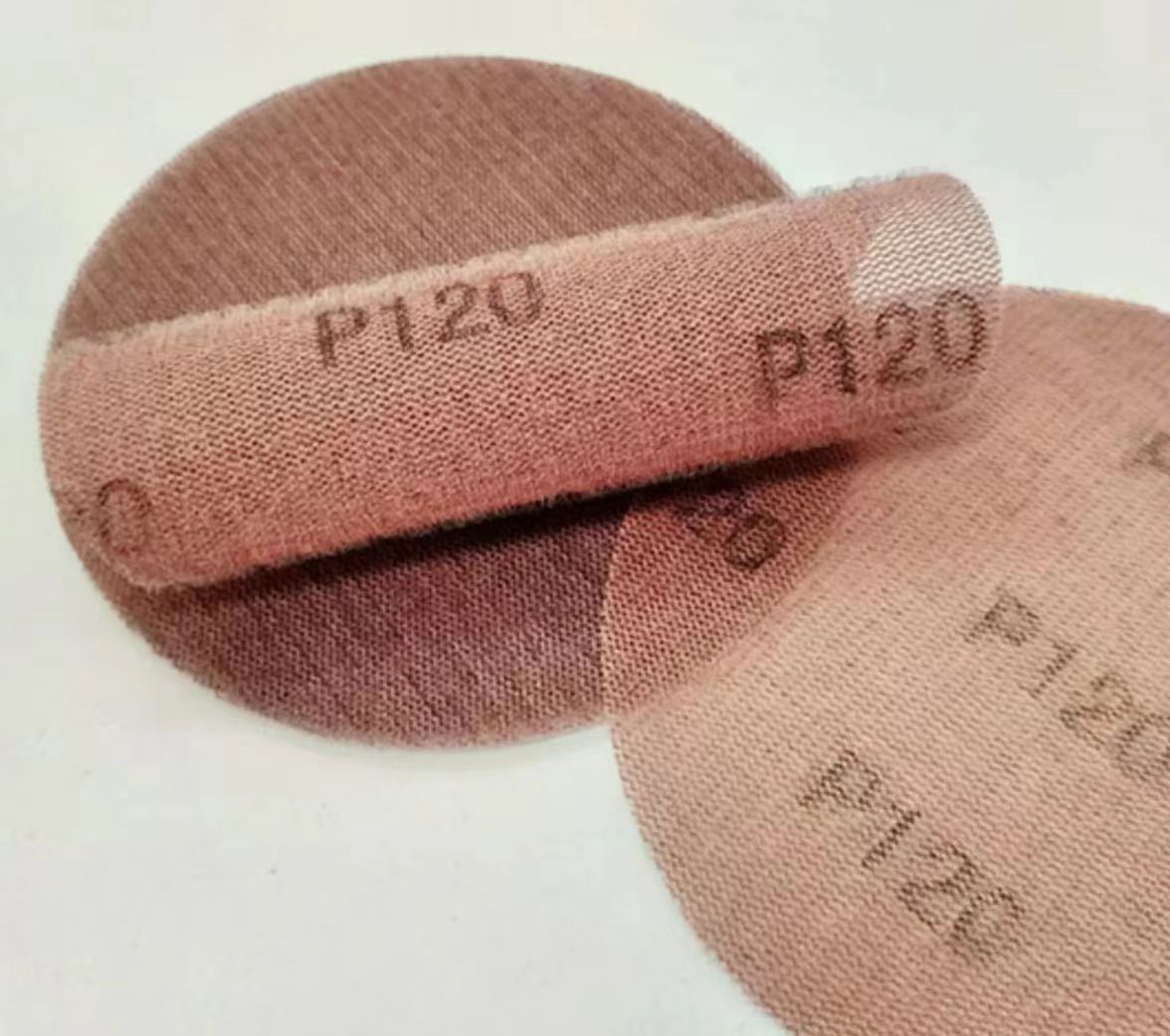

3D mesh fabric is a base material used for abrasive Net.

it has emerged as a revolutionary material in the realm of abrasivenet, offering unique advantages that enhance performance and durability. Its distinctive three-dimensional structure, characterized by interconnected layers and uniform porosity, makes it an ideal candidate for abrasive applications.

One of the key benefits of 3D mesh fabric in abrasivenet is its exceptional ability to retain abrasive particles. The structure (three-dimensional framework) creates numerous cavities and interstices, ensuring secure adhesion of abrasives such as aluminum oxide or silicon carbide. This not only enhances the cutting efficiency but also prolongs the lifespan of the abrasivenet by preventing premature abrasive loss.

Moreover, the porous nature of 3D mesh fabric facilitates efficient debris removal during grinding or polishing processes. The interconnected channels allow for unobstructed flow of air and coolant, reducing heat buildup and minimizing clogging. This results in consistent performance and a smoother finish on the workpiece.

Additionally, the inherent flexibility and strength of 3D mesh fabric enable abrasivenet to conform to irregular surfaces while maintaining structural integrity. It can withstand high levels of mechanical stress, making it suitable for heavy-duty applications in industries such as metalworking, woodworking, and automotive manufacturing.

In conclusion, 3D mesh fabric brings significant improvements to abrasivenet, combining enhanced abrasive retention, efficient debris clearance, and robust durability. Its application paves the way for more effective and reliable abrasive processes across various industrial sectors.